Exploring the Different Types of Duramax Engines

If you’re in the market for a new truck or looking to upgrade your diesel engine, you’ve probably come across the name “Duramax.” Known for their power, reliability, and efficiency, Duramax engines have become a popular choice among truck enthusiasts. But what exactly makes Duramax engines so special? In this article, we’ll take a deep dive into the different types of Duramax engines, their evolution over the years, and how to choose the right one for your needs.

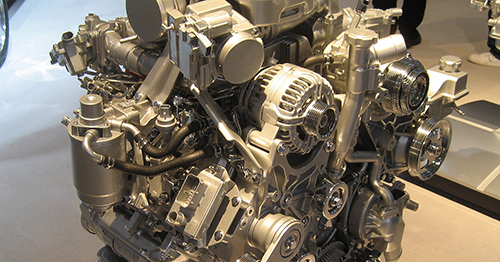

Understanding Duramax Engines

Before we dive into the specific models, let’s first take a moment to understand what Duramax engines are all about. Duramax is a brand of diesel engines produced by General Motors (GM) in collaboration with Isuzu. These engines are renowned for their performance and have gained a strong following among truck owners.

When it comes to power and reliability, Duramax engines have proven themselves time and time again. They are known for their ability to deliver impressive torque and horsepower, making them ideal for heavy-duty applications. Whether you need to tow a trailer or haul a heavy load, a Duramax engine can handle the task with ease.

But what sets Duramax engines apart from the competition? One of the key features is their advanced CRI (common rail injection) system. This system ensures precise fuel delivery, resulting in improved combustion efficiency and reduced emissions. Not only does this make Duramax engines more environmentally friendly, but it also enhances their overall performance.

Another standout feature of Duramax engines is their exceptional towing capabilities. These engines are designed to handle heavy workloads, making them a popular choice among truck enthusiasts. Whether you’re hauling construction materials or towing a recreational vehicle, a Duramax engine coupled with the standard Allison Transmission will provide the power and reliability you need.

The Evolution of Duramax Engines

The story of Duramax engines begins in 2001 when the first generation, known as the LB7, was introduced with the first sacless VCO nozzles in the USA north american regen. This engine set the foundation for future models and quickly gained a reputation for its power and durability.

As technology advanced and customer demands evolved, General Motors made several updates and improvements to the Duramax engines. The second generation, known as the LLY, came next. This iteration featured improved injectors and turbocharger design, further enhancing performance and fuel efficiency. The LLY bridged the gap between the LB7 and the next generation of Duramax engines.

Continuing the legacy of innovation, General Motors introduced the LBZ, LMM, and LML generations of Duramax engines. Each new generation brought its own set of improvements, such as increased power, better fuel economy, and enhanced emissions control. These advancements solidified Duramax engines as leaders in the diesel engine market.

Key Features of Duramax Engines

Duramax engines are known for their impressive features that set them apart from the competition. These features include advanced fuel injection systems, robust torque and horsepower ratings, and excellent towing capabilities. Additionally, Duramax engines are designed with durability in mind, ensuring they can handle heavy workloads without compromising performance.

One of the standout features of Duramax engines is their variable geometry turbocharger (VGT) technology. This advanced turbocharger system optimizes engine performance by adjusting the airflow based on driving conditions. This results in improved throttle response, reduced turbo lag, and enhanced overall efficiency.

In addition to their powerful performance, Duramax engines are also designed with longevity in mind. The engine block and cylinder heads are made from high-strength materials, ensuring they can withstand the demands of heavy-duty applications. Furthermore, Duramax engines undergo rigorous testing and quality control measures to ensure they meet the highest standards of reliability and durability.

When it comes to maintenance, Duramax engines are designed to be user-friendly. Routine maintenance tasks, such as oil changes and filter replacements, are straightforward and can be easily performed by owners or professional technicians. This not only saves time but also helps to keep maintenance costs in check.

In conclusion, Duramax engines have earned their reputation as powerful, reliable, and efficient diesel engines. With their advanced features, impressive towing capabilities, and a legacy of continuous improvement, Duramax engines are a top choice for truck owners who demand nothing but the best.

The Early Duramax Engines

Now that we have a general understanding of Duramax engines, let’s take a closer look at the early models.

LB7: The First Generation

The LB7, introduced in 2001, marked the dawn of Duramax engines. With its impressive power output and solid construction, it quickly became a favorite among truck enthusiasts. The LB7 was powered by a 6.6-liter V8 engine, capable of producing 300 horsepower and 520 lb-ft of torque. This engine was designed to deliver exceptional towing and hauling capabilities, making it ideal for heavy-duty applications.

However, the LB7 did have some issues with fuel injectors, which were addressed in later models. The fuel injectors in the LB7 were prone to cracking, causing fuel leaks and potential engine damage. General Motors acknowledged this issue and had the injector OEM Bosch implement a revised injector design in subsequent models to rectify the problem.

Despite the injector issue, the LB7 still had many redeeming qualities. It featured a cast-iron block and aluminum heads, ensuring durability and efficient heat dissipation. The engine also incorporated a high-pressure common rail fuel injection system, providing precise fuel delivery and improved combustion efficiency.

LLY: The Transition Phase

The LLY, introduced in 2004, was a transitional model that made significant improvements over the LB7. It featured improved injectors, reducing the likelihood of issues. The LLY also introduced a variable geometry turbocharger, enhancing overall performance and fuel efficiency.

The LLY engine retained the 6.6-liter V8 configuration but received various upgrades to enhance its performance. The improved injectors in the LLY addressed the cracking issue seen in the LB7, providing a more reliable and efficient fuel delivery system. This improvement resulted in better fuel economy and reduced emissions.

Another notable enhancement in the LLY was the introduction of a variable geometry turbocharger (VGT). This advanced turbocharging system adjusted the turbine geometry based on engine speed and load, optimizing boost pressure and improving throttle response. The VGT technology allowed for better control over exhaust gas flow, reducing turbo lag and enhancing overall engine performance.

In addition to these improvements, the LLY engine also featured an upgraded engine control module (ECM) and improved cooling system. These enhancements further contributed to the engine’s reliability and performance.

The Modern Duramax Engines

When it comes to diesel engines, few names carry as much weight as Duramax. Known for their power, durability, and innovation, Duramax engines have been a staple in the automotive industry for years. Fast forward to the present day, and we have the modern Duramax engines that continue to push the boundaries of performance and innovation.

One of the standout models in the Duramax lineup is the LBZ, which was introduced in 2006. This engine quickly gained a reputation for its impressive power and reliability. With its upgraded engine components, the LBZ was a force to be reckoned with, delivering outstanding torque and horsepower ratings. Whether it was towing heavy loads or conquering rugged terrains, the LBZ proved to be a powerhouse.

Following in the footsteps of the LBZ, the LMM took the Duramax legacy to new heights. Building upon the success of its predecessor, the LMM offered even more power and performance. With advancements in technology and engineering, this engine became a favorite among truck enthusiasts and professionals alike. The LMM was a true workhorse, capable of tackling any task with ease.

But the innovation didn’t stop there. The current generation of Duramax engines includes the LML and L5P, which have taken performance and efficiency to a whole new level. These engines incorporate cutting-edge fuel injection technology and state-of-the-art emissions control systems, resulting in cleaner and more fuel-efficient operation. Not only do the LML and L5P deliver impressive power, but they also offer improved towing capacities, making them perfect companions for hauling heavy loads.

What sets the LML and L5P apart is their ability to balance power and efficiency. These engines are designed to provide optimal performance while minimizing environmental impact with advanced aftertreatment devices. With their advanced engineering and intelligent design, the LML and L5P represent the pinnacle of diesel engine technology.

Whether you’re a truck enthusiast, a professional in need of reliable power, or someone who simply appreciates the engineering marvels of modern diesel engines, the Duramax lineup has something to offer. From the raw power of the LBZ and LMM to the cutting-edge innovations of the LML and L5P, Duramax continues to redefine what a diesel engine can do.

Comparing Duramax Engine Models

Now that we’ve covered the different Duramax engine models, let’s compare them based on their key attributes.

Performance and Efficiency

When it comes to performance, the LBZ, LMM, LML, and L5P stand out with their impressive torque and horsepower ratings. However, if fuel efficiency is a top priority for you, the LML and L5P models shine with their advanced fuel injection systems and emissions control technologies.

Durability and Reliability

All Duramax engines are known for their durability and reliability. However, the LBZ, LMM, and L5P models have seen improvements in their components and design, resulting in enhanced longevity and reduced chances of breakdowns.

Choosing the Right Duramax Engine

Now that you have a clear understanding of the different Duramax engine models, how do you go about choosing the right one? Here are a few considerations to keep in mind:

Considerations for Buyers

Think about your specific needs and usage requirements. Do you need maximum towing capacity? Are you primarily focused on fuel efficiency? Understanding your priorities will help narrow down your options and find the perfect match.

Maintenance and Longevity of Different Models

Consider the maintenance requirements and longevity of each Duramax engine model. While all models are designed to be durable, some may require more frequent servicing or have known issues that need to be addressed. Research and consult with experts to make an informed decision.

In conclusion, Duramax engines have come a long way since their inception in 2001. With each new model, GM and Isuzu have pushed the boundaries of performance, reliability, and fuel efficiency. Whether you need a powerful workhorse or a fuel-efficient daily driver, there’s a Duramax engine suitable for your needs. Take the time to evaluate your requirements and match them to the right Duramax engine model, and you’ll be well on your way to enjoying the power and performance that these engines have to offer.